- #Great cut contour cutting from corel draw 2019 manual

- #Great cut contour cutting from corel draw 2019 registration

- #Great cut contour cutting from corel draw 2019 software

- #Great cut contour cutting from corel draw 2019 professional

Is the most user-friendly out of these 4 cutters.Is the most expensive of these 4 cutters.Cuts at a slower speed than the Refine MH-721 and PCut 24″.Has a built-in laser for contour cutting.Cannot be used with CoredDraw or Adobe Illustrator.Has a material detector to tell if material is loaded.Highest listed downforce of these 4 cutters.May not work with other graphics software, like CorelDraw.

#Great cut contour cutting from corel draw 2019 software

These inexpensive cutters may not have the features and durability of mid-grade cutters but they still work as a great starting point or a backup.

#Great cut contour cutting from corel draw 2019 professional

Watch this video to find out if it’s time to invest in a professional vinyl cutter.

#Great cut contour cutting from corel draw 2019 registration

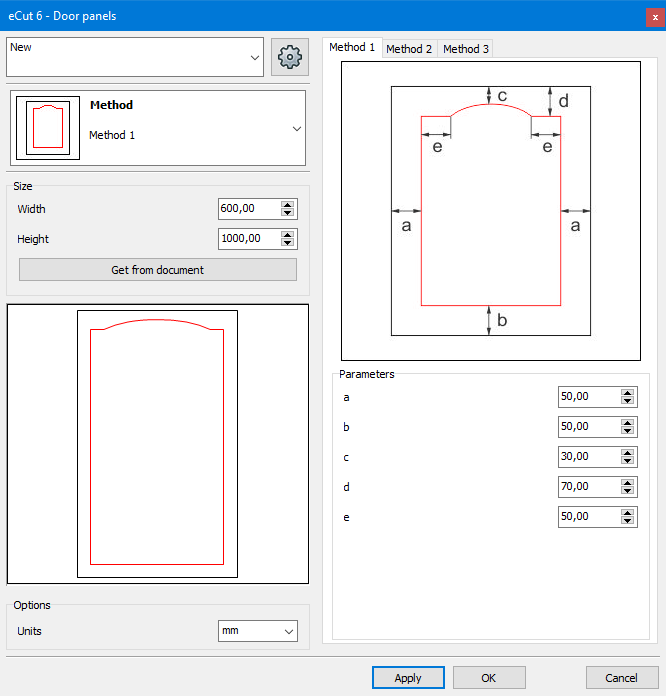

If the software is capable of managing intra-device registration and the hardware is able to output the proper data to the software, then you can contour cut with something resembling precision. This process depends far more on the software than on the hardware. In other words, it can adjust the logical map to the actual territory. The registration process of reading back the marks, either automatically or manually, serves to allow the software to adjust itself to accommodate where the marks actually are versus where it thinks they might be. The software prints the marks where it thinks they should be and knows that they exist. What you do need is cutter software capable of reading these reference points back from the cutter, inferring the axes from these readings, and adjusting itself accordingly.

#Great cut contour cutting from corel draw 2019 manual

You can print a 3 or preferably 4 point set of manual marks and locate them with a light pen, bomb sight, or even the cutter blade. You don't need an automatic mark sensing apparatus.

0 kommentar(er)

0 kommentar(er)